Intralogistics

Intralogistics systems play an important role in the automated in-plant transport of materials in factories, distribution centers, parcel services, warehouses, airports, hospitals, and others. These systems increase efficiency, quality, sustainability, and traceability of material flow processes, while reducing waste and inventory buffers. Without them, modern high performance facilities could not function. Electrification components are needed for intralogistic equipment as Automated Guided Vehicles ( AGV), Electric Monorail Systems ( EMS), electric pallet conveyors, rail guided vehicles (RGV), transfer cars, and baggage handling systems, as well as sorters, automated storage and retrieval systems (AS/RS, stacker cranes) and shuttle systems.

Intralogistic systems must be available on demand. If part of the system goes down, processes before and after will stop and the entire facility could shut down. Also, any required maintenance must be done quickly and easily. Energy and data transmission components must adapt to high performance systems, often with complex layouts and operating at high speeds and acceleration. At the same time, they must provide maximum energy efficiency at an acceptable cost. Some systems must meet special technical challenges, such as “clean room” and food processing environments, refrigerated storage, or impure production lines.

Conductix-Wampfler has extensive experience working with intralogistics system OEMs worldwide. From our large product portfolio, we can recommend the optimum solution for individual applications across many different industries without bias towards single technology. With our global presence and local support, we partner closely with OEMs and end-user customers for both small and large scale projects, striving for technical optimization with minimum complexity. Our continuous research & development efforts are geared towards new solutions and continuous improvements of products for this industry.

Inductive Power Transfer (IPT) – powers systems such as AGVs and baggage handling systems. New generations of IPT with state-of-the-art features keep pace with our customers needs.

Conductor Rails – power Electrified Monorail Systems ( EMS), Rail Guided Vehicles (RGV), and baggage handling systems. The SinglePowerLine 0812 and MultiLine 0831, combined with ProShell are ideal for AS/RS stacker cranes. MultiLine 0835 and MultiLine 0365 are the perfect match to power shuttle systems. PEplus for conductor rails works well for electric conveyors of all types, providing safety and simplicity.

Spring-Driven and Motor-Driven Reels – manage cables used to power transfer cars and other moving equipment.

Rubber and Cellular Buffers – are well suited to absorbing energy from machine element impacts.

Jay Radio Remote Controls – offer a safe way of operating or monitoring machines from a distance. The comprehensive range of industrial and safety radio remote controls offers countless solutions to adapt to an extensive number of intralogistic applications.

-

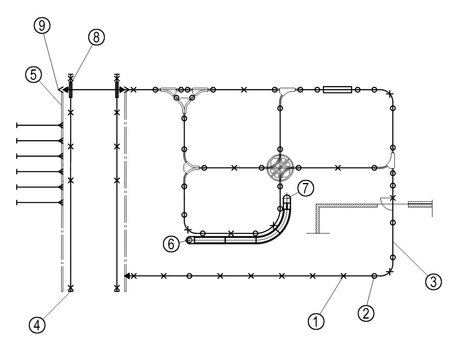

Overhead Monorail system with Shifting Bridge in a Paint finishing system

Reference Report

[REF0400-0006-E]

Overhead Monorail system with Shifting Bridge in a Paint finishing system

Application

Overhead Monorail system with shifting Bridge in a Paint finishing system

Operator

Technocol, Praha, (CZ)

Customer

S.O.F. s.r.o

Product

Program 0400

Additonal information

C-Profile 40x40 mm Fivefold equipment Crane with span length L=6000 mm

Relevant Products

Manual - C-Rail Program

Additional information

For transport within a facility, Conductix-Wampfler’s modular handling systems can provide customized transport solutions that ensure an optimum material flow. Various additional components, such as switching systems and curves, allow for the creation of complex tracks. The modular nature of the system and its simple assembly make it possible to plan and install a manual suspension track for many different applications.

Product data

Manual suspension tracks offer the following benefits:

- Low investment costs

- Reduced internal transport time

- Reduced handling times

- Increased productivity

- Easier working conditions for employees

- Targeted material flow

- Product-based design

- Easy expansion of the system at any time

- Individual construction with custom set-ups

- Flexible adjustment for changes in production requirements

- Simple planning with a clearly laid out modular system

Manual suspension track components

- Rail carriers

- Rail connectors

- Track rails [fixed length of C-rails: 6m], include cut-off in calculations

- End stop with a safety screw

- Safety guides for keeping the transported object in place

- Drag chain conveyor - drive station

- Drag chain conveyor - tensioner

- Interlock mounted on the crane bridge

- Arrester mounted on the spurs

Downloads

Equipment Bridges / Tool Bridges

Additional information

Conductix-Wampfler device bridges can be used to provide optimum coverage for large work areas. Various models are available in different sizes based on customer specifications. The energy supply is available with electric supply only, compressed air only or a combination of the two. The simple handling of the system is another benefit.

Energy supply options for the equipment carrier

- Compressed air

- Electric

- Compressed air and electric

Energy supply options for the tool transporter

- Compressed air

- Electric

- Compressed air and electric

Energy supply options for turntables

- Compressed air

- Electric

- Compressed air and electric

Product data

Versions

- Single girder device bridge with a equipment carrier

- Single girder device bridge with a tool transporter

- Double girder device bridge with a turntable

- Double girder device bridge with a tool transporter

Downloads

Conductix-Wampfler Power & Data Transmission Equipment China

Shanghai - Sales & Marketing Center

Room 1002-1005, Ruihong Corporate Avenue T1

No.118 Feihong Road

Hougkou District, Shanghai 200086 P.R. China

China

Phone: +86 (21) 6840 7060

Fax: +86 (21) 6896 8310

www.conductix.com.cn

info.cn@conductix.com

Conductix-Wampfler Power & Data Transmission Equipment China

Wuhan - Production Center

No.2 Xingye Zhonglu

Jiangjun Street

Dongxihu District

Wuhan 430040

China

Phone: +86 (27) 8349 9988

Fax: +86 (27) 8349 9989

www.conductix.com.cn

info.cn@conductix.com

- 2 more clicks for privacy: By clicking here, the button becomes active and you can send your recommendation to Facebook. With the activation data will be transmitted to third parties.mit Facebook verbunden

- 2 more clicks for privacy: By clicking here, the button becomes active and you can send your recommendation to Twitter. With the activation data will be transmitted to third parties.nicht mit Twitter verbunden